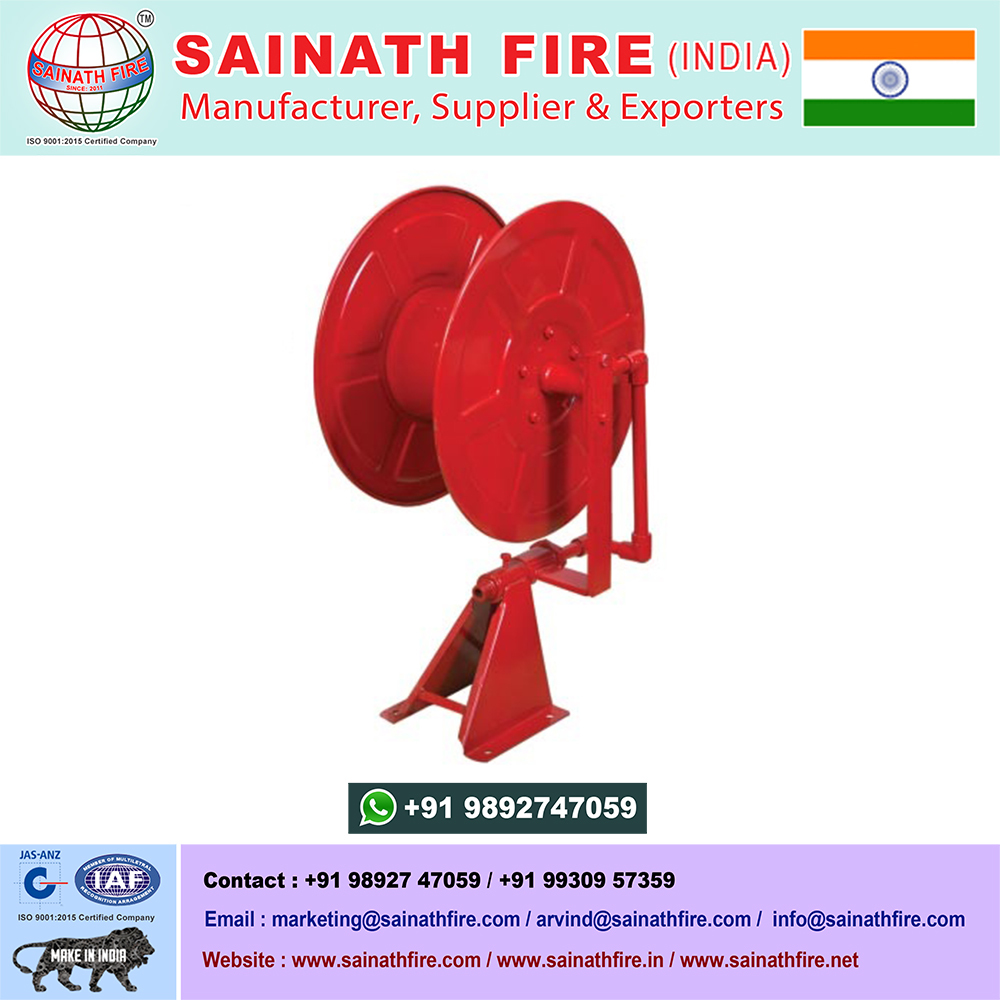

Fire Hose Reel Drum

Fire Hose Reel Drum Specification

- Hardness

- Medium (as per IS 884:1985 specifications)

- Shape

- Round Drum with wall mounting

- Cover

- Red powder coated steel

- Medium

- Water

- Reinforcement

- High tensile synthetic textile

- Connection Type

- Inlet 1 or 1.5 Male/Female Threaded

- Material

- Mild Steel / Stainless Steel

- Temperature

- -20C to +60C

- Pressure

- 1.6 MPa (16 Bar)

- Inside Diameter

- 19 mm or 25 mm

- Outside Diameter

- Varies as per model, typically 22 mm or 28 mm

- Hose Length

- 30 meters or custom lengths

- Mounting Type

- Wall Mounted, Swinging or Fixed type

- Marking

- Standard 'FIRE HOSE REEL' as per IS specifications

- Nozzle Type

- Jet/Spray Nozzle shut off type

- Rotation

- 180 for swinging type

- Operating Method

- Manual unwinding

- Weight

- Approx. 18-22 kg including hose and nozzle

- Drum Diameter

- Approx. 500 mm

- Finish

- Epoxy/Red Powder Coated

- Drum Width

- Approx. 180 mm

- Hose Type

- Rubber or Thermoplastic (IS 444 / IS 636 compliance)

Fire Hose Reel Drum Trade Information

- Minimum Order Quantity

- 10 Pieces

- FOB Port

- MUMBAI

- Delivery Time

- 1 Days

- Main Domestic Market

- All India

About Fire Hose Reel Drum

Fire Hose Reel Drum

Hose Reel Drum TECHNICAL SPECIFICATION Hose Reel Drum IS:884/1958 Size Inlet 1 Threaded Inlet Connection Swinging Type 180 Degree Wall Mounting Outlet / 1 Outlet Connection For Hose 30 MTR. 36 MTR. 40MTR & 45 MTR. Hydro. Test 21kgf/cm2 Water flow rate Test 7kgf/cm2 Discharge 24 LPM Jet Lenth 6 MTR. (MIN) Hub Side and wall Bracket M.S. Sheet of IS:513 Swivel Joint LTB-2 of IS:318 Pipe with Fitting Steel of IS:1239 Hose Reel Tubing Tharmoplastic Hose Hose Reel Swinging Type Wall Mounted Hose Reel Drum With years of expertise in this domain we are involved in delivering large assortment of Fire Hose Reel Drum. Manufactured in accordance with the parameters of the industry, these are mainly used in shopping centers, fire stations and hotels. Features: Compact design Low maintenance Superior performance Optimum quality

Customizable Fire Hose Reel Solutions

Our fire hose reels can be configured with hoses of varying lengths and inside diameters to meet unique needs. Both swinging and fixed wall-mounted reels allow users to quickly access water in emergencies. Nozzle options include a jet/spray shut-off for targeted or broad water delivery, enhancing firefighting capability across a range of settings.

Superior Safety Standards and Construction

Fabricated with mild or stainless steel and finished in epoxy or red powder coating, each drum meets IS 884:1985 and IS 444/IS 636 standards. The reinforced design resists corrosion and wear, providing secure containment and rapid access to water. Marking and specifications meet national safety requirements for dependable operation.

FAQs of Fire Hose Reel Drum:

Q: How do you operate the Fire Hose Reel Drum during an emergency?

A: To use the Fire Hose Reel Drum, manually unwind the hose from the reel, ensuring the nozzle is directed toward the fire source. If using a swinging type, rotate the drum up to 180 for optimal reach. Open the shut-off nozzle, selecting either jet or spray mode depending on the situation.Q: What are the advantages of choosing rubber or thermoplastic hoses for the reel?

A: Both rubber and thermoplastic hoses comply with IS 444 or IS 636 standards. Rubber is known for its flexibility and abrasion resistance, while thermoplastic offers lightweight handling. Both provide durability in demanding environments and withstand a temperature range of -20C to +60C.Q: When should you opt for a fixed versus a swinging type hose reel?

A: A swinging hose reel is ideal when coverage across a wider area is needed, as it can rotate up to 180. Fixed reels are suitable for confined spaces or areas where a designated hose direction is sufficient. Your selection should be based on the layout and fire safety requirements of your facility.Q: Where is the best location to install a wall-mounted Fire Hose Reel Drum?

A: Install the drum in accessible locations on escape routes, near exits, or high-risk zones such as manufacturing areas or workshops. Ensure the wall is strong enough to support the assembly and that the hose can reach all parts of the protected area.Q: What is the process for customizing hose length and diameter?

A: Customers can specify hose lengths up to 30 meters (or custom) and choose inside diameters of 19 mm or 25 mm when ordering. Our manufacturing process then produces each drum to these exact specifications, ensuring precise fit and performance.Q: How does the reinforcement and finish enhance the drums durability?

A: The high tensile synthetic textile reinforcement strengthens the hose, reducing the risk of bursting under pressure. The epoxy or red powder-coated steel drum resists corrosion and weathering, providing long-term reliability even in challenging environments.Q: What benefits does compliance with IS 884:1985, IS 444, and IS 636 offer?

A: Compliance with these standards ensures the hose reel and hose are tested for durability, performance, and safety. Users can trust the equipment during emergencies, meeting insurance and legal requirements for fire safety in India and international markets.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hose Reel Drum & Hose Box Category

Hose Box

Price 3500.00 INR

Minimum Order Quantity : 1 Piece

Medium : Other, Water

Material : Other, Mild Steel

Connection Type : Female Threaded Coupling

Hardness : Durable Construction

Foam Hose Reel With Tank Stainless Steel

Price nan INR

Minimum Order Quantity : 1 Piece

Medium : Other, Foam and Water

Material : Other, Stainless Steel (Tank), Rubber (Hose)

Connection Type : Brass Couplings and Nozzle

Hardness : Shore A 65 5

Stand Mounted Hose Reel

Price 250.00 INR

Minimum Order Quantity : 1 Piece

Medium : Other, Water

Material : Other, PVC

Connection Type : Threaded Coupling

Hardness : Shore A 655

Fire Extinguisher Cabinet

Price nan INR

Minimum Order Quantity : 1 Piece

Medium : Other, Dry Powder, CO2, Foam, or Watertype extinguisher

Material : Other, Highimpact, UV stabilized ABS/polycarbonate/plastic or steel construction

Connection Type : Front hinged door with lock or latch

Hardness : Shore D 6080

Send Inquiry

Send Inquiry